Naphtha Splitter

Location

Port Arthur, Tx

Market

Refining

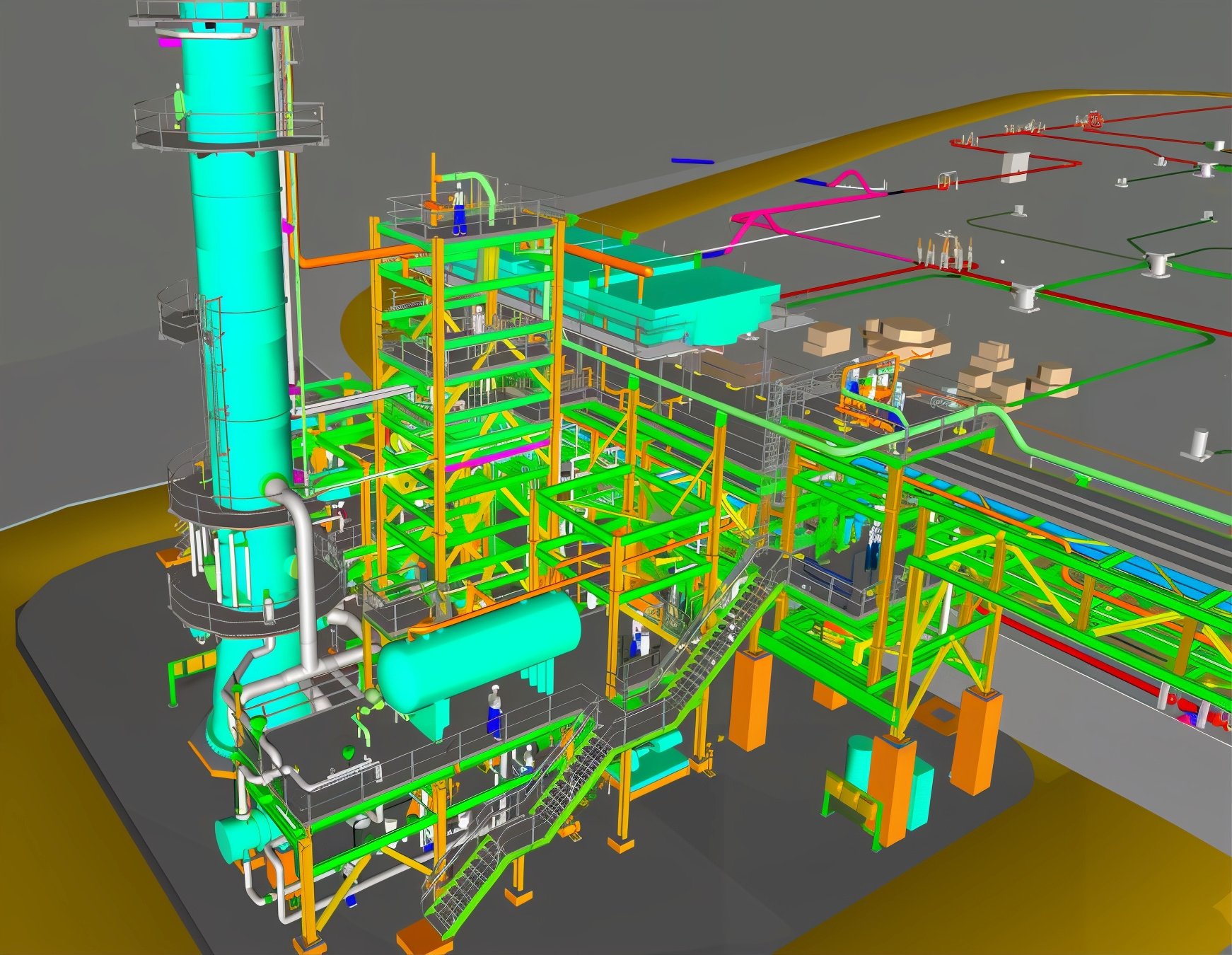

We performed FEL2/3, detailed engineering, and provided procurement assistance for a grass-roots unit integrated with a new Delayed Coking Unit. The design emphasized maximum modularization, allowing the field contractor to achieve nearly 100% fit-up of all process modules on-site. This approach significantly reduced field labor hours, optimizing both cost and schedule.

The process unit featured a dual-column split tower, overhead condenser/receiver, reboilers, heat exchangers, and more. Additionally, all electrical systems and SIS/DCS equipment were seamlessly integrated with the infrastructure supporting the new Delayed Coking Unit.